Although the Society of Motor Manufacturers and Traders (SMMT) predicts that battery electric vehicles will capture a 17.8 per cent share of the new car market by the close of 2023, they remain a topic of fervent discussion and sensational headlines. Tyres aren’t exempt from this discourse, as the Daily Mail made clear in July when calling them the “dirty secret behind your electric vehicles.” To bring some common sense back into the EV tyre conversation, Michelin recently shared its views on the subject.

There’s no dirty, tabloid secret – the added weight of batteries, paired with greater torque, mean that electric cars typically wear out tyres faster than their combustion engine equivalents. Marika Hoflund, managing director of Michelin’s Nordic region business, shared a few figures with us at an event in Sweden, a country where plug-in EV market share exceeds 60 per cent. Amongst other things, she mentioned that compared with combustion vehicles, tyre treads wear up to 20 per cent faster when fitted to EVs.

“Tyres with a lifespan of 50,000 kilometres on a combustion engine car will roll 12,000 kilometres less when used on an electric car before wearing to the legal limit of 1.6 millimetres tread depth on summer tyres.” Hoflund considers this a “very significant difference” but is quick to point out that not all tyres are created equal. She adds that Michelin has worked hard to find solutions to this and other challenges.

Qualities relevant to all cars

One solution that tyre makers now offer is specific EV-suitable tyres, and here Hoflund has some good news. “All Michelin tyres are suitable for electric vehicles thanks to their intrinsic qualities such as rolling resistance, wear, noise, abrasion and grip. These are qualities not only relevant to EVs, but to all cars.”

Hoflund comments that “a good rule of thumb is that there is a correlation between price and quality,” which is one way of describing the premium pricing of Michelin tyres. She confirms that “EV suitable tyres will come at an added cost for consumers” but stresses that tyre buyers need to look at whole-life cost rather than just initial purchase price. The managing director also warns that equipping EVs with “average ICE tyres” may prove “more expensive in the long run” due to their faster wear and the effect of this upon rolling resistance. Equally important for Hoflund and Michelin is the “very heavy” impact of standard tyres upon our planet through wear-related particle emissions.

A big difference

With microplastic emissions from tyres an issue that upcoming Euro 7 standards intend to address, Michelin’s interest in this area is more than piqued. Hoflund’s colleague Richard Andermyr confirms that the tyre maker supports the implementation of set thresholds for tyre particle emissions. Andermyr, sustainability manager for Michelin in Sweden, emphasises that there is a “big difference” between the best and worst performing tyres in this area.

Using figures gleaned from Dekra testing of more than 2,000 tyres between 2013 and 2018 as well as results extrapolated from Auto Bild all-season tyre testing, Michelin estimates that a set of four of its CrossClimate 2 tyres driven for 20,000 kilometres (12,427 miles) will release 1.5 kilograms of particles into the environment. This is less than half the “market average” 3.5-kilogram particle emissions over 20,000 kilometres, while the worst performing tyres release 8 kilograms of particles.

“There is a big difference, and it can have a huge impact,” Andermyr comments. Michelin has worked to alleviate the problem of tyre abrasion by focusing upon the materials within its tyres as well as tyre construction, and its efforts have resulted an approximately five per cent reduction in Michelin tyre particle emissions since 2015. When German motoring association ADAC recently examined almost 100 summer and winter tyres in a range of popular sizes and patterns, it found that average abrasion and particle emissions would decrease by 28 per cent if all vehicles ran on Michelin tyres.

Before Michelin considers a tyre sustainable, it must maintain key performances, including safety at a low tread depth (Photo: Stephen Goodchild / Tyre Industry Publications Ltd)

Driving to the last millimetre

In addition to minimising wear and particle emissions through how it builds tyres and the raw materials it uses, Michelin champions another practice – one that also reduces average rolling resistance and therefore fuel consumption.

Michelin began focusing on rolling resistance more than three decades ago and brought its first optimised tyre to market in 1992. This was the Michelin Energy, and it achieved rolling resistance of approximately 12 kg/T, a very good result for the time. Rolling resistance for current products such as the Michelin e.Primacy and Pilot Sport EV is just half this. Andermyr says the tyre maker “wants to go further” with its optimisation measures and aims to decrease rolling resistance by a further ten per cent between 2020 and 2030. Tyre construction and materials will continue to play a role here, but so will Long Lasting Performance.

At the heart of Michelin’s Long Lasting Performance campaign is a commitment to develop tyres that offer safe driving performance right up until the legal tread depth limit of 1.6mm. Michelin is arguably the strongest supporter of 1.6mm tyre changes, with some manufacturers and tyre associations recommending the replacement of tyres at a much more conservative 3mm or even 4mm tread depth.

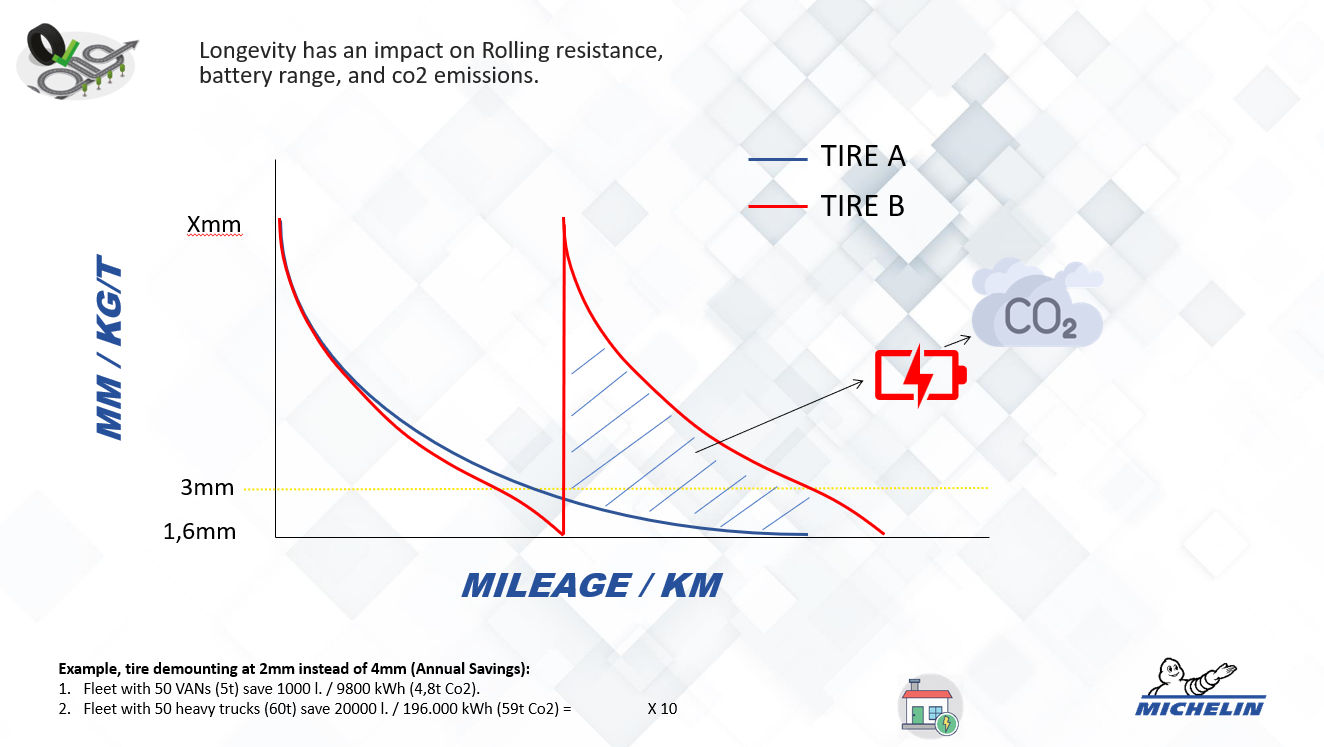

The lower the tread depth, the more slowly a tyre wears and emits microplastics, as there is less movement in the tread blocks and less heat build-up. The final 1.4mm of tread before the legal limit may account for a fifth of the tyre’s lifespan. Andermyr also explains that replacing tyres at 1.6mm substantially reduces average rolling resistance too.

Tyre use & rolling resistance

Imagine two tyres, one that is removed from the vehicle when it still has 3mm of tread remaining and a tyre that continues in use until the tread wears down to 1.6mm. Andermyr tells us that although rolling resistance declines roughly parallel to tread depth throughout the entire life of the tyre, the biggest drop in rolling resistance occurs during the final millimetre or so before 1.6mm. “As the tread depth is lower there is less movement in the tread, which results in less rolling resistance.”

Whereas the tyre we keep using until 1.6mm (we’ll call this Tyre A) continues in service and encounters less and less rolling resistance, when we remove the other tyre (Tyre B) at 3mm we replace it with a new tyre. This substitute Tyre B brings with it a new, unworn tread whose blocks move more. This results in higher rolling resistance. “All this energy that is saved with Tyre A is lost to Tyre B, reducing battery range,” says Andermyr. Michelin calculates that a fleet of 50 vans (each weighing up to 5 tonnes) could save 9,800 kWh by demounting tyres at 2mm instead of 4mm, an amount equal to 1,000 litres of fuel.

“A huge amount of energy is lost by not using tyres all the way down, and that is why we are working so hard on lasting performance so that our tyres become better when they are worn and are safe when they’re worn,” Andermyr adds. “This is extremely important.”

Blazing a trail

Andermyr concludes by summarising the Michelin solution to the weight, wear and range challenges posed by electric vehicles. “We want to create tyres that reduce their environmental footprint. We want the tyre to maintain key performances, including safety at a low tread depth, and we need to mass produce those tyres. Only then can we call them sustainable.”

“With the help of tougher yet flexible rubber compounds in combination with other new materials in the tyre, we’re striving to counteract the extra wear and tear on electric cars,” adds Marika Hoflund. “As of late, many other tyre manufacturers have started on the same journey as us, introducing different versions of tyres for hybrid and electric cars that promise to reduce rolling resistance and to give more kilometres on a charge. This trend shows that we’ve been on the right path all along with our tyre development, and I’d say we’ve blazed a trail for the tyre market in this regard.”